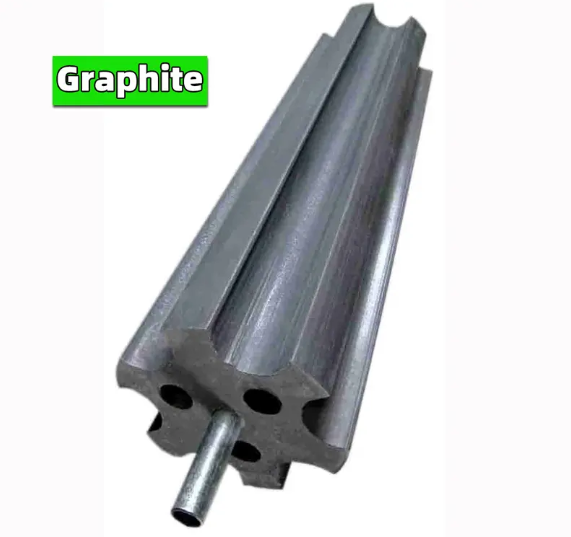

Understanding Graphite Electrodes and Their Role in Grounding

Graphite electrodes serve as high-performance materials in grounding systems. They enhance electrical contact properties, ensuring firm grounding even in soils with high corrosion rates or extreme temperatures. Their excellent conductivity and cylindrical design make them ideal for physical grounding. Graphite electrodes offer a cost-effective solution compared to copper, thanks to their abundance and ease of mining. The demand for these electrodes has surged due to technological advancements in steel manufacturing, which require stable materials for modern electric arc furnaces. Grounding Graphite Electrodes play a crucial role in maintaining safety and efficiency in electrical systems.

Properties of Graphite Electrodes

Conductivity

Graphite electrodes exhibit exceptional conductivity, making them ideal for grounding applications. Their ability to conduct electricity efficiently stems from their unique structure. The carbon atoms in graphite form layers that allow electrons to move freely, enhancing electrical flow. This property ensures that graphite electrodes can handle high currents without overheating or degrading.

Scientific Research Findings:

- Graphite electrodes offer remarkable electrochemical properties, including excellent conductivity and mechanical stability. These characteristics make them suitable for various industrial applications where reliable electrical performance is crucial.

Resistance to Corrosion

Graphite electrodes also demonstrate impressive resistance to corrosion. This quality is particularly important in environments with high corrosion rates or extreme temperatures. Unlike metals that may corrode over time, graphite maintains its integrity, ensuring long-term reliability in grounding systems.

The chemical inertness of graphite contributes to its durability. It resists chemical reactions that could otherwise compromise its structure. This resistance extends the lifespan of graphite electrodes, reducing the need for frequent replacements and maintenance.

Applications of Grounding Graphite Electrodes

Grounding Graphite Electrodes find extensive use in various applications due to their superior electrical properties and durability. Their ability to maintain performance in challenging environments makes them a preferred choice for grounding systems.

Industrial Grounding Systems

In industrial settings, Grounding Graphite Electrodes play a vital role in ensuring safety and operational efficiency. Industries often face harsh conditions, such as high temperatures and corrosive environments. Graphite electrodes excel in these situations due to their resistance to corrosion and excellent conductivity.

Electric Arc Furnaces: These electrodes are commonly used in electric arc furnaces, where they withstand high temperatures and facilitate efficient electrical grounding. Their cylindrical design enhances performance, ensuring stable operations.

Chemical Plants: In chemical plants, where exposure to corrosive substances is frequent, graphite electrodes provide reliable grounding. Their chemical inertness prevents degradation, ensuring long-term functionality.

Power Generation Facilities: Power plants utilize Grounding Graphite Electrodes to maintain electrical stability. Their ability to handle high currents without overheating ensures uninterrupted power supply and safety.

Performance Insight: Research indicates that graphite significantly improves electrical resistivity behavior while maintaining mechanical properties crucial for grounding purposes. This makes them an ideal choice for industrial applications.

Residential and Commercial Grounding

Grounding Graphite Electrodes also serve residential and commercial sectors effectively. Their adaptability and cost-effectiveness make them suitable for various grounding needs.

Residential Buildings: In homes, these electrodes ensure safe electrical grounding, protecting appliances and inhabitants from electrical faults. Their durability reduces maintenance needs, offering a long-term solution.

Commercial Complexes: For commercial buildings, reliable grounding is essential to protect sensitive equipment and ensure safety. Graphite electrodes provide efficient grounding, minimizing risks associated with electrical surges.

Public Infrastructure: Public facilities, such as schools and hospitals, benefit from the stability offered by Grounding Graphite Electrodes. Their consistent performance ensures the safety and reliability of electrical systems.

The versatility and effectiveness of Grounding Graphite Electrodes make them indispensable across various sectors. Their ability to enhance electrical safety and efficiency underscores their importance in modern grounding systems.

Advantages of Graphite Electrodes Over Other Materials

Durability and Longevity

Graphite electrodes stand out for their remarkable durability and longevity. These electrodes resist wear and tear, even under aggressive conditions. Unlike copper electrodes, graphite ones achieve electrode wear of less than 1 percent relative to the depth of cut. This feature ensures that they last longer, reducing the need for frequent replacements.

Their chemical inertness further enhances their lifespan. Graphite resists chemical reactions that could degrade its structure. This resistance makes graphite electrodes ideal for environments with high corrosion rates or extreme temperatures. Industries benefit from this durability, as it leads to lower maintenance costs and increased operational efficiency.

Efficiency in Conductivity

Graphite electrodes excel in efficiency when it comes to conductivity. They hold more current compared to copper electrodes, resulting in higher metal removal rates. This ability to conduct electricity efficiently stems from their unique structure. The carbon atoms in graphite form layers that allow electrons to move freely, enhancing electrical flow.

Despite having lower conductivity than copper, graphite electrodes offer excellent heat resistance and cost-effectiveness. Their ability to withstand high temperatures without degrading makes them suitable for various industrial applications. Moreover, their cost-effectiveness arises from their abundance and ease of mining, providing a more economical option for industries.

Key Insight: Graphite electrodes provide a balance between conductivity and durability, making them a preferred choice over copper in many applications. Their ability to maintain performance under challenging conditions underscores their value in modern grounding systems.

Graphite electrodes exhibit exceptional electrochemical properties, making them a reliable choice for grounding systems. Their applications span industrial, residential, and commercial sectors, where they ensure safety and efficiency. These electrodes offer advantages such as durability, longevity, and cost-effectiveness over other materials.

Key Benefits:

- Exceptional conductivity and resistance to corrosion.

- Cost-effective and durable, reducing maintenance needs.

Future Trends:

- Innovations in bioelectrochemistry and energy storage.

- Potential use in environmental analysis and electrochemical sensors.

Graphite electrodes continue to evolve, promising advancements in grounding technology and beyond.